We were honored to take on this project, as it’s one that was close to our hearts. Our tasks for this project included, but were not limited to rebar mapping and utility locating for concrete scanning.

Monitoring the state of bridge decks is an ongoing need to evaluate deterioration. Corrosion of reinforcing steel and delamination of asphalt and concrete can be sensed with GPR. This example illustrates an area of chemical alteration in a bridge-deck. Deterioration is indicated by changes in signal amplitude.

Bridge decks require regular inspection.

GPR has proven to be a very effective method of non-destructively evaluating degradation and delamination. The ASTM # D6087 standard describes the principles for using GPR for this purpose.

RoadMap GPR is optimized to conduct bridge deck investigations.

Our SmartTrailer with multiple sensors facilitates acquisition of data at highway speeds to minimize traffic management costs. Our hand-push SmartCart® units enable detailed local studies when lane closure is planned for other reasons.

CityScan Corp used an integrated ground penetrating radar (GPR) system used for locating objects in concrete prior to cutting and coring. It’s critical that all objects are properly marked out to prevent damage and more importantly, personal injury.

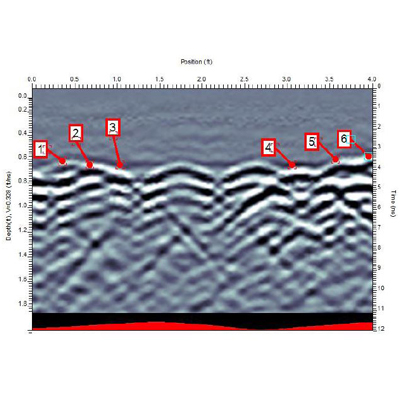

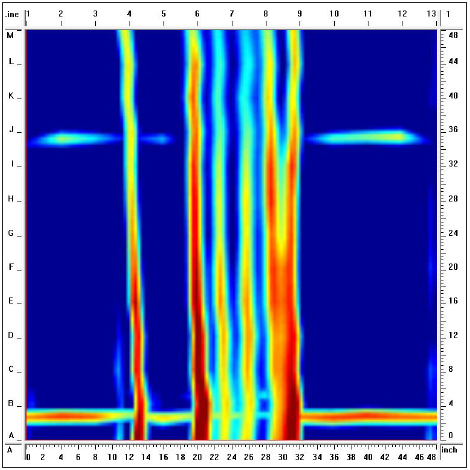

During a condominium renovation project, a series of holes needed to be drilled for the installation and routing of plumbing lines. CityScan Corp. was called in to scan the area with GPR prior to coring. We started by using our state of the art equipment, however we quickly observed the congestion of embedded objects in the slab which was making interpretation very challenging.

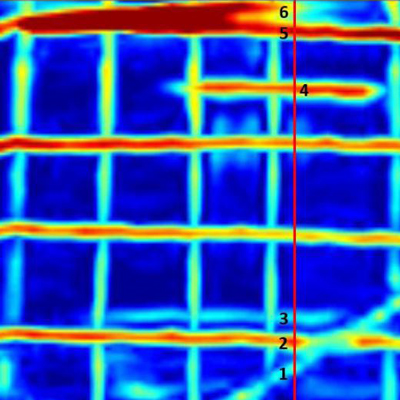

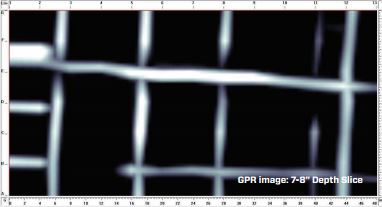

We went into Grid Scan mode and setup a 4′ x 4′ grid on the system. A grid scan is done by collecting multiple lines in the X and Y directions and then processing the data to generate a series of depth slices. Figure 1 shows one of the depth slices at 7″ – 8″ deep. The cross–section image in Figure 2 corresponds to the red vertical line shown in Figure 1.

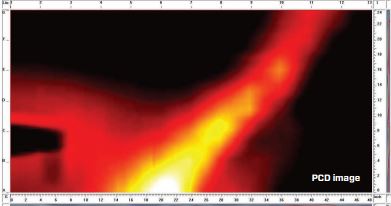

When cutting and coring, early warning of the presence of electrical cables in concrete reduces the risk of costly damages and injury. CityScan Corp. combines power cable detection (PCD) with traditional GPR responses to provide a new dimension to concrete imaging: two technologies more.

PCD measures the magnetic fields created by current flow in electrical wiring. When wiring is embedded in or beneath concrete, PCD enhances the user’s ability to distinguish electrical cables from other structures.

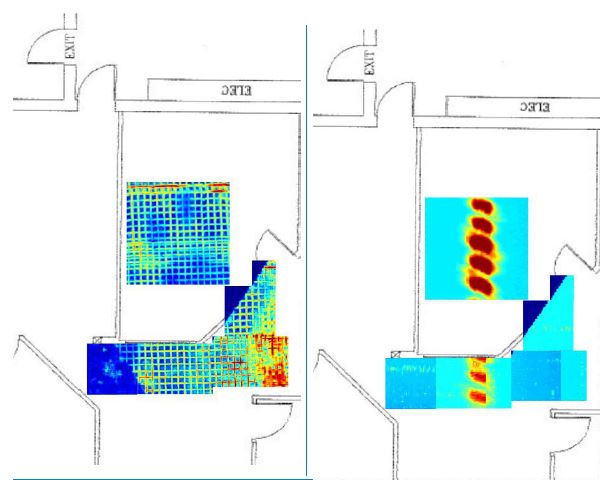

This sheet shows examples of PCD responses, correlated with the GPR depth slices. By looking at both results, users can greatly reduce the number of incidents when cutting and coring. PCD is standard on all Conquest systems.

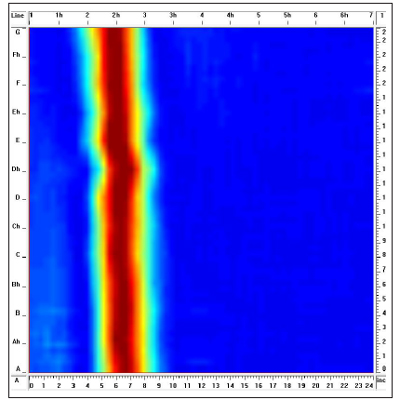

A recent building renovation required mapping the precise location of the main power line entering the building under the slab-on-grade floor. CityScan Corp.’s ground penetrating radar (GPR) with PCD (Power Cable Detection) provided a quick and easy solution.

Many low rise buildings with concrete slab-on-grade floors have poor documentation of utility connections that were placed under the slab. GPR provides a powerful way of mapping out the subslab installations. In this case study, the lead-in from the street to the building was not well defined at the front of the building. The power feed disappeared under the concrete floor and emerged at a panel in the center of the building.

We used our state of the art GPR equipment with PCD (Power Cable Detector) to locate the power cable path. The added benefit of the integrated PCD sensor is that it can detect live power cables and simplify data analysis.

An initial 8′ ×8′ grid was established in a meeting room adjacent to the power panel since this was the probable route for the cable.

The PCD data was collected simultaneously with the GPR data and the results superimposed on a floor plan.

Locating radiant heat tubing in a concrete slab using GPR

Ground Penetrating Radar is an effective tool for mapping out all embedments in concrete. Whenever concrete is cut or cored knowing what is in the slab is critical for worker safety and to prevent damage to the structure. Being able to differentiate between various objects in a slab allows for cost effective decisions to be made.

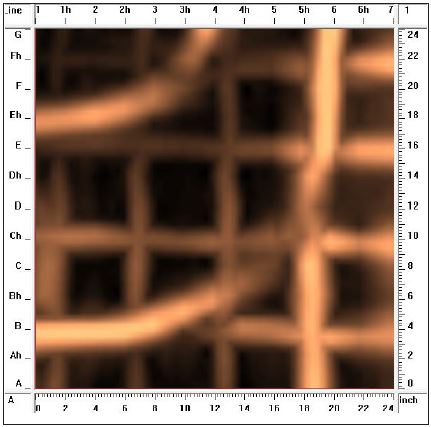

We were asked to core a series of 3″ holes through a concrete slab. Normally this would be a simple enough task, however upon inspection it was noted that the slab contained in-floor heating. Even a small “nick” in one of these tubes would cause significant damage and put the project way over budget. It was determined that the tubes must be located before any coring could begin.

To minimize the risk of hitting a tube, GPR was used to scan each of the drill locations. Our quick grid collection and rapid on–board processing allowed for each drill site to be scanned and cleared in a matter of minutes.

Thanks to the use of GPR all holes were drilled without damage to the reinforcement or the in-floor heating tubes. The technology served to efficiently prevent any damage without delaying coring. This resulted in the project moving forward on schedule and on budget.

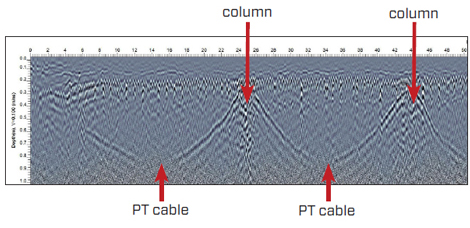

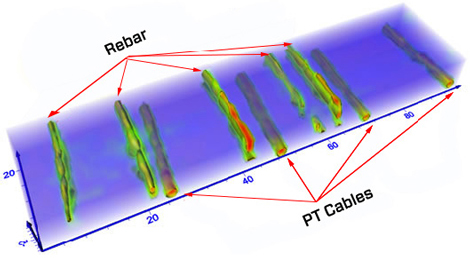

3D visualization of location of underground utilities, rebar and post-tension cables embedded in a concrete slab. An expanding mall recognized that their shortage of parking spaces was going to become a limiting factor in their future development. They decided to renovate and build an addition onto the existing parking garage, providing the structure was sound and would support the planned addition.

The mall had changed owners a number of times and no as-built drawing existed that detailed the construction of the old structure. One of the key points of interest was the position of post tension (PT) cables throughout the levels.

Post–tension cables are used in concrete construction to allow thinner slabs and greater span lengths between support columns. These cables, composed of steel wires inserted into a plastic sheath, are subsequently “tensioned” and grouted after the concrete is poured.

The engineering company hired also recognized that the contractors who would eventually be hired to do the renovation would have to avoid cutting any of the cables. The tremendous tension in the cable makes cutting it dangerous for the operator and compromises the structure’s integrity.

Sample areas of interest were chosen to be scanned with ground penetrating radar (GPR) so the internal structure of the parking garage could be determined. Our flexibility allowed the scanners to collect grids over large and small areas quickly.

The unique aspects of post-tension cables allows GPR imaging to identify these features with a high level of certainty.

The areas scanned on the old parking garage provided a clear answer. Post-tension cables were present throughout the structure. This is clearly shown in the depth slice image. The red vertical lines show the PT cables bundled together at a tight spacing.

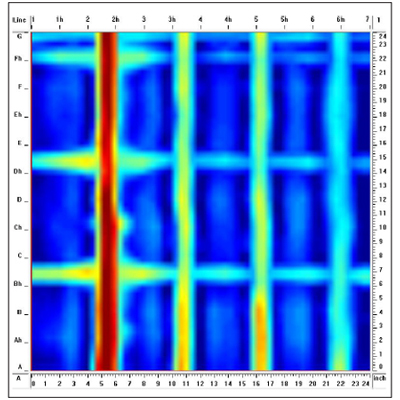

PCD (Power Cable Detector) prevents electric cable strike. A warehouse and office extension was planned for an old manufacturing facility. Many renovations had occurred at the site over the years with little documentation. This left the engineering firm and the contractor working on the current project with little knowledge of where utilities ran throughout the structure.

Confirming the as-built construction at the design stage allows planners to optimize placement of new infrastructure. On this project it was clear that some long cuts would need to be made in the existing slab on grade. Due to the complex operations of the facility it was known that many conduits and electrical cables ran through the concrete. Striking a live power cable was a real hazard on this project and something had to be done to mitigate the risk.

GPR was brought on site to scan concrete slab structures and identify embedments and, in particular, locate live power cables to protect the cutting crew. On one occasion, the GPR operator found an anomalously strong response from a reinforcing member but no indication of the expected conduit. In order to get a clearer picture of what was happening in the concrete a 24″ × 24″ grid was collected. When viewing the map of live power cables over the same area, a strong power response was noted. This lined up with the strong GPR response, suggesting that the rebar and the power cable were located side by side.

Subsequent coring and chipping confirmed that an electric cable was located close to a rebar. The GPR anomaly was indeed the combined response of the rebar and the electrical cable. The cutting crew was able to avoid potential injury and the project continued on schedule.

This case study demonstrates the power of CityScan Corp.; combining the two technologies provides more definitive indication of embedded live power cables. Some key observations are:

As we strive for the best service in the industry, CityScan Corp has teamed up with Eastern Concrete Cutting Corp. to offer our clients a reliable source for all their concrete cutting and drilling needs.

To learn more on Eastern Concrete Cuttings services,

visit www.EasternCutting.com